#Data Printing Retrofit

Explore tagged Tumblr posts

Text

#carton inspection system#variable data printing#print inspection system#Variable data inkjet printing machines#Data Printing Retrofit#Digital Inkjet Printing Technology

1 note

·

View note

Text

Dexterous mechanical fingers flicked through archaic printed after-action reports. Lifeless eyes took in their whole contents at once; the pictures Sone took could be easily parsed later in her "mind's eye," stored now as data and filed away for easy locating. One after another. Flick. Snap. Save. Flick. Snap. Save.

Her consciousness drifted over her storage architecture. There was little room given over to business not of UGN's interest. A few songs, although she preferred to listen to them externally. Some books as well, for the same reason as the songs: sometimes Sone's robotic nature lent her well to long stake-outs or sentry duty, and it helped to have something around for passing the time. A few pictures of places and things she found interesting. A few of her current friend, safe until she drives them away and purges the evidence just like always. One of her twin.

She lurched. Her brain tingled in its casing. Readings spiked for a moment. Electricity surged down her cerebellum and into her nerve column. The resistors kicked on in an instant. Heat began to build, then vent from her arms automatically. Her twin.

She set the papers down, standing quickly. With heavy footsteps she retreated, back into her bath. It was ironic, she had remarked, that she was given a facility that she couldn't use, but it was intended to make her feel more "human" again. Or too difficult to retrofit a standard-issue room, even for an accomplished agent. But it was discrete. Click. The door closed behind her.

She briefly considered deleting the photo again. Every time she did, it was never more than a few weeks before she scanned in the original again. It wasn't worth the risk. Not with her family gone. The image of her twin sister was irreplaceable. The last reminder of what she looked like before the accident. Before she became Flatline. Before she stopped being human. Stopped being human. Stopped being human.

She fell, crouched down on her knees, hands on her head. She always wandered, as her analytical mind desperately looked for an escape, if this was a normal attack or the work of the virus. Either way, she was woefully underequipped to process the welling panic. Because she wasn't human. She died. Maybe she's still dead. Maybe she's just a ghost. Maybe she's a program made by Dr. Ban to fill a suit. Maybe the real Sone is inside of her, and until Flatline dies the little girl will be trapped forever. Maybe she was in hell.

She wished she could cry, but her body was a rushed affair, incapable of showing any emotions. She couldn't even scream without great effort and consent. Terror and sorrow for her took a very strange look. She would lock up, unmoving, and begin to overheat. Steam filled the bathroom, pouring out from her auxiliary hent vents now. Her resistors would need replacing again. Because of how weak she was being.

She looked at the photo again. Black hair. Tanned skin. Smiling. God, smiling. Was she ever happy? What was she even like back then? Did she have *any* interests? Why does she forget her sister's face every time until she stumbles upon the photo again? Her parents were already gone, appearances lost to time. Why did those four people, that loving family, have to die just for this zombie to walk away from it all?

She stood carefully, the air thick and murky with vapors. She stepped towards the mirror. A hand reached up. Wipe.

The face revealed was white, nearly porcelain. Intense eyes with pale iris's darted back and forth. An unmoving mold of a subtle pair of lips sat under a near-featureless impression of a nose. Messy straight white hair dangled down. She had looked like this for 6 years. She didn't recognize the machine in the mirror for the entire time. She was in a nightmare. What had she been doing all this time? Working as a killing machine, feeling her brain wither away as it was denied the normal functions of a human for so long. It was unfair to real humans to assume their identity. It was an insult to them.

Servos whirred with unimpeded movement, electricity arcing across her frame. Her resistors were failing, one by one. Circuits frying, unnatural lightning coursing through phantom wires, guided by habit. Her hand drove through the mirror, into the wall. This was all a ruse, a lie she could tell herself. The truth was much darker. She could feel the human within her, pounding against its metallic cage, begging to get out or die. But there was no way out, and she could not die. She was stuck in her frame, stunted and built for war. She wanted to be pretty again.

Combat and self-preservation subroutines competed for control. The robot in the shattered mirror was an enemy that she could not bring herself to destroy. Even then, the virus would not let her die.

The door opened. Steam poured out into the room. A darkened figure stood beyond. Her fear and lethal instincts turned to the shape. A raised arm split to reveal a long barrel. Sparks built bridges between the polished metal and surrounded walls, kept from burning only by the grace of their ceramic construction. She fired. But the form was too quick.

Arms around her. What tactile sensors still worked detected fur. Well cared for, unlike when her and Sone first met. The arms gripped, hard. A reliable strength. Stubborn claws dug in. Her lightning pored into the figure, along with her residual heat. Smoke from burning hair. A voice.

"I'm here, Sone."

Flatline's arm folded in. The gun disappeared.

"You're okay."

Her vents began to close. The killer programming settled down.

"You haven't hurt me."

Sone's arms and legs went limp. The wolf girl followed her down.

"I'm here."

The machine powered down. Her brain slowly cooled off. The human stuck in the cage steadied its breathing and wiped away its tears. It reached a hand out of its cage, making the mistake of reaching for comfort once again.

Sone wrapped her arms around Alina. Mechanical fingers buried themselves into the wolf's coat. What energy she had left was spent crushing Striga with all her might, holding for dear life. Striga was strong enough to manage, squeezing Sone back just as tight.

#vent writing#my ttrpg comfort otp#i wanna write more with them later#striga#flatline#double cross#stories from the witch#dx3rd

3 notes

·

View notes

Text

Flexo automation and the shift to digital and hybrid labels

The pressure-sensitive label industry in India continues to grow as packed and labeled products in numerous types of containers, formats, and sizes multiply. Every food and snack product is available in various exotic and localized flavors. You can now buy packs of Hershey’s chocolates filled with California almonds with guava and Mexican chilli flavor, or Hershey’s Exotic Dark blueberry and acai flavored centers. Also, you can find Mazan chocolate cubes filled with paan flavour and many other products in the market with a variety of localized flavors including Kurkure packs with ‘UP Taste.’ In short, the number of SKU’s of pouches and labeled containers have substantially multiplied.

It is no longer about flexo versus digital versus flexo. At the Labelexpo India in 2022, the European plate and roller manufacturers said that ‘digital is the death of flexo.’ To bolster their views they pointed to challenges such as print density, banding, and handling newer substances – a virtual laundry list of difficulties with digital label production.

Digital printing has found its place in various label applications, especially when personalization, variable data, and shorter print runs are required. Flexo holds significant advantages in terms of cost-effectiveness in large-volume production runs and printing on certain materials and increasingly for short-run flexible packaging, especially with the widespread availability of locally manufactured presses.

Managing shorter print runs is challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding flexo units to a digital module in a hybrid configuration, or investing in a digital roll-to-roll press alongside established flexo lines has helped converters adopt a more sustainable ‘print-on-demand’ business model for shorter-run labels and packaging.

Hybrid printing can be a more sustainable and economical approach. “The flexo technologies being retrofitted with add-on features to a digital press are referred to as hybrid,” explained Ajit Bharadwaj of Vinsak. “Features such as variable data printing, foiling, stamping, die-cutting, and more automated features are increasingly in demand among converters. Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock,” he said.

Parwez Izhar, senior vice president of the printing cylinders business at UFlex shares that the Indian packaging industry is witnessing a surge in smart packaging that features technologies such as track-and-trace systems integrated into labels and packaging including RFID, NFC, QR codes, holograms, and more.

Izhar explains that approximately 20% of the gravure market share has shifted to flexo, primarily due to its cost-effectiveness and faster turnaround time. He says, “In the label industry, both flexo and digital are gaining ground, and with the increasing demand for short-run jobs, converters are also turning to digital.”

“However, converters are not focusing on just one approach, they are thinking about growth. Many opt for both technologies—if they have flexo, they add digital. Converters recognize the demand for a premium look and feel, so the future lies in hybrid technologies that can meet all the quality, volume, and variable data requirements,” Izhar adds.

The automated flexo presses that include hybrid LED UV systems, die-cut units, pre-register, auto-register, movable turn bar, lam and relam units, peal and seal kits, and foiling stations for labels, shrink sleeves, and flexible packaging are increasing in global demand. Faridabad-based Multitec’s mid-web flexo presses can print on various substrates including thin and extensible materials with capability ranging from 10 microns up to 450 microns at 200 meters a minute with impressive registration and low setup wastage.

Multitec generally leads the industry in new technology adoption and implementation with 40% of its manufacturing being exported. Amit Ahuja, managing director of Multitec explained, “The growing short-run demand is creating a market space for digital. This does not pose any threat to veteran flexo users – but the future is in the hybrid production of labels together with the increasing demand for more automation features and quicker and more precise make-ready solutions.”

0 notes

Text

Sandwich Panel Market 2025 Size, Share, Growth, Market Supply and Demand, Company Profiles, Trends, Component & Growth with Forecast

Sandwich panels have revolutionized various industries with their versatility, durability, and efficiency. These composite structures, consisting of two face sheets bonded to a lightweight core material, offer excellent thermal insulation, soundproofing, and structural integrity. The Sandwich Panel Market has been experiencing significant growth, driven by expanding construction activities, the demand for energy-efficient solutions, and advancements in material technologies.

Sandwich Panel Market Size was valued at USD 2.32 Billion in 2024. The sandwich panel industry is projected to grow from USD 2.53 Billion in 2025 to USD 5.42 Billion by 2034, exhibiting a compound annual growth rate (CAGR) of 8.9% during the forecast period (2025 - 2034).

Growing Construction Sector: One of the primary drivers propelling the sandwich panel market is the booming construction industry. With rapid urbanization and infrastructure development worldwide, there's a heightened demand for high-performance building materials that offer both sustainability and cost-effectiveness. Sandwich panels, with their ability to enhance energy efficiency and accelerate construction timelines, have become a preferred choice for residential, commercial, and industrial projects. From residential housing to warehouses, data centers to cold storage facilities, the versatility of sandwich panels is evident across diverse construction applications.

Focus on Energy Efficiency: In an era marked by increasing environmental consciousness and stringent regulations, energy efficiency has become a paramount concern for building owners and developers. Sandwich panels, with their superior thermal insulation properties, help reduce energy consumption and carbon emissions, thereby contributing to sustainability goals. The emphasis on green building practices and energy-efficient designs is driving the adoption of sandwich panels in both new constructions and retrofit projects. Governments worldwide incentivize the use of eco-friendly building materials, further bolstering the demand for sandwich panels in the construction sector.

Technological Advancements: Continuous innovation in material science and manufacturing processes has led to the development of advanced sandwich panel solutions. Manufacturers are investing in research and development to enhance the performance characteristics of sandwich panels, including fire resistance, acoustic insulation, and structural strength. The integration of cutting-edge technologies such as nanotechnology and 3D printing is opening up new possibilities for optimizing the properties of sandwich panels while reducing production costs. Additionally, the advent of smart building technologies has spurred the demand for sandwich panels embedded with sensors and IoT capabilities for real-time monitoring and control.

Market Challenges and Opportunities: Despite the favorable growth prospects, the sandwich panel market faces certain challenges, including volatile raw material prices, regulatory complexities, and competition from alternative building materials. Moreover, the COVID-19 pandemic has disrupted supply chains and construction activities, temporarily impacting market growth. However, as economies recover and construction projects resume, the demand for sandwich panels is expected to rebound swiftly. Manufacturers can leverage this opportunity by diversifying their product offerings, expanding into emerging markets, and embracing sustainable practices to gain a competitive edge.

Future Outlook: The sandwich panel market is poised for robust expansion in the coming years, driven by factors such as urbanization, infrastructure development, and the growing emphasis on sustainability. As the construction industry evolves, sandwich panels will continue to play a pivotal role in shaping the built environment, offering innovative solutions for architects, developers, and building owners. With ongoing advancements in materials, technologies, and design capabilities, the future of the sandwich panel market looks promising, promising sustainable, efficient, and aesthetically pleasing building solutions for the world's growing population.

MRFR recognizes the following Sandwich Panel Companies - DANA Group of Companies (UAE),INVESPANEL SL (Spain),Kingspan Group (Ireland),Building Component Solutions LLC (Saudi Arabia),Nucor Corporation (U.S.),Assan Panel A.S. (Turkey),Hoesch Siegerlandwerke GmbH (Germany),ArcelorMittal S.A. (U.S.),MANNI Group (Italy),Zhong Jie Group (China),Romakowski GmbH & Co. KG (Germany),Tata Steel Limited (India),NCI Building Systems Inc. (U.S.),Multicolor Steels India Pvt Ltd. (India),Sintex (India)

Related Reports

Vacuum Insulation Panel Market - https://www.marketresearchfuture.com/reports/vacuum-insulation-panels-market-2438 Polycarbonate Panels Market - https://www.marketresearchfuture.com/reports/polycarbonate-panels-market-7851

1 note

·

View note

Text

CNC Controller Market Size, Share & Industry Growth Analysis Report 2030

The global CNC controller market size is expected to be USD 3.23 billion in 2025 and is projected to grow at a CAGR of 4.8% from 2025-2030 to reach USD 4.08 billion by 2030. The CNC controller market is driven by the increasing demand for automation of manufacturing processes that increase precision and efficiency. The advancement in the industry 4.0 technologies, including the Internet of Things and AI, helps accelerate the usage of smart CNC systems. The economic and time-efficient production requirement and the growing automobile and aerospace industries fuel further market growth. More importantly, the rising prevalence of custom machinery and the trend toward miniaturization in electronic devices stand out among catalysts.

Driver: Increasing adoption of industrial automation in the global manufacturing sector

The primary reason for the need for industrial automation in the global manufacturing industry is due to the need for real-time data monitoring and predictive maintenance. The benefits that accrue from automation are many, including higher precision, better quality products, accuracy, safety, and consistency in the production processes. It also increases productivity and reduces operation costs, a huge advantage for automotive, aerospace, and medical equipment manufacturing industries. Probably because companies are trying to increase automation and improve their production processes, there is an expected increase in the use of advanced technologies, like CNC machines.

Restraint: High investment and long-term maintenance cost

Introducing CNC controllers is an enormous economic burden both due to the very high initial cost and the high maintenance cost. The above costs are especially challenging to SMEs characterized by limited capital. The cost of the machinery, aside from that, required infrastructure upgrades, including power supply enhancements, a dedicated workspace, and environmental controls to ensure optimal performance of CNC systems.

Once it becomes operational, the monetary obligations will only continue with maintenance and operational expenses. CNC controllers need servicing, too, to get precise and efficient commands and would therefore consider necessary periodic checks, adjustments, and replacement of key parts, including drive motors, spindles, and sensors. Software updates are necessary to improve performance, minimize cyber risks, and bring them up to current industry standards, but this usually comes at a charge in licensing or subscription fees.

Opportunity: Integration of 3D printing technology with CNC machining.

Integrating CNC controllers with 3D printing creates a significant opportunity for augmenting precision through hybrid manufacturing that combines additive and subtractive techniques. This approach would make complex parts possible, minimizing the post-processing needed, enhancing accuracy, and reducing lead times. Mass customization, reduction of material waste, and consistency with sustainability goals are also promoted. It will integrate CNC-3D printing, thus becoming the future of smart, efficient, and flexible manufacturing through real-time adaptation and seamlessness in switching between processes.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=133889642

Challenge: Integration of Modern CNC Controllers with Legacy Systems

Integrating modern CNC controllers with legacy systems will raise significant challenges to manufacturers working on older machinery. The primary problems are that legacy hardware, software, and communication protocols are not compatible with newer advanced CNC controllers that use digital communication, IoT connectivity, and real-time data exchange. This often requires costly custom interfaces and retrofitting the older machines with newer motors, drives, and sensors for compatibility.

0 notes

Text

Pneumatic Knife Holders, Global Market Size Forecast, Top 19 Players Rank and Market Share

Pneumatic Knife Holders Market Summary

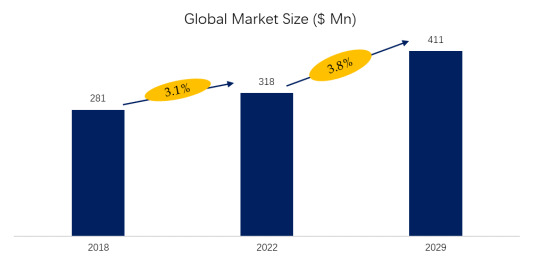

According to the new market research report “Global Pneumatic Knife Holders Market Report 2023-2029”, published by QYResearch, the global Pneumatic Knife Holders market size is projected to reach USD 0.41 billion by 2029, at a CAGR of 3.8% during the forecast period.

Pneumatic knife holders are devices used in industrial cutting and machining processes to hold and control the position of cutting tools, particularly knives or blades. These holders use pneumatic (air) pressure to secure the knife in place and provide controlled movement during cutting operations. Pneumatic knife holders are commonly used in various industries, including printing, paper converting, packaging, and textile manufacturing.

Picture from Spares Service & Machinery

Figure. Global Pneumatic Knife Holders Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Pneumatic Knife Holders Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

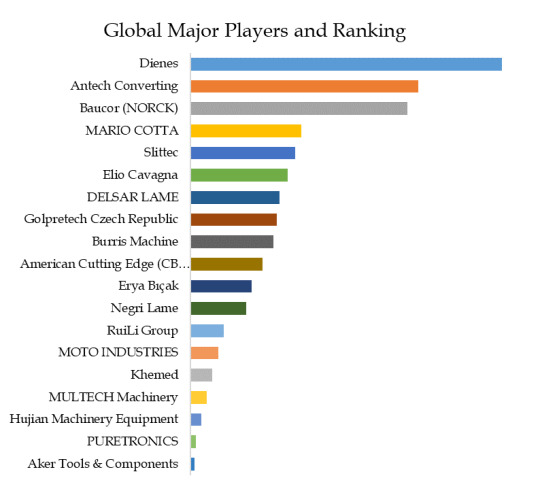

Figure. Global Pneumatic Knife Holders Top 19 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Pneumatic Knife Holders Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Pneumatic Knife Holders include Dienes, Antech Converting, Baucor (NORCK), MARIO COTTA, Slittec, Elio Cavagna, DELSAR LAME, Golpretech Czech Republic, Burris Machine, American Cutting Edge (CB Manufacturing and Sales), etc. In 2022, the global top five players had a share approximately 55.0% in terms of revenue.

Market Drivers:

Increased Automation in Manufacturing: The growing trend toward automation in manufacturing processes, including cutting operations, drives the demand for pneumatic knife holders. These holders can be integrated into automated systems to enhance precision, efficiency, and overall productivity.

Demand for Precision Cutting Solutions: Industries that require precision cutting, such as printing, packaging, and textiles, seek advanced cutting solutions. Pneumatic knife holders provide the necessary precision, contributing to the demand for these holders in applications where accurate cuts are critical.

Diverse Industrial Applications: Pneumatic knife holders find applications in a diverse range of industries, including paper converting, packaging, textiles, and more. The versatility of these holders makes them suitable for various materials and cutting requirements, leading to broader market adoption.

Restraint:

Cost Considerations: The initial cost of pneumatic knife holders, including the purchase and installation, can be a significant factor influencing the decision-making process for potential buyers. Industries may be hesitant to invest in these holders if the upfront costs are perceived as high, especially for smaller businesses with budget constraints.

Maintenance Requirements: Pneumatic knife holders, like any industrial equipment, require regular maintenance to ensure optimal performance. The ongoing costs associated with maintenance, including replacement parts and labor, can contribute to the total cost of ownership and may be a consideration for potential buyers.

Complexity in Integration: Integrating pneumatic knife holders into existing manufacturing systems, especially in cases of retrofitting, can be a complex process. Compatibility issues and the need for adjustments or modifications to accommodate the holders may pose challenges for some industries.

Opportunity:

Integration with Industry 4.0 Technologies: The integration of pneumatic knife holders with Industry 4.0 technologies, such as sensor systems, connectivity, and data analytics, can enhance overall efficiency and provide insights for predictive maintenance. Smart and connected knife holders contribute to the evolution of smart manufacturing.

Development of Lightweight and Compact Designs: Opportunities exist for manufacturers to develop lightweight and compact pneumatic knife holders. These designs can be particularly advantageous for applications where space is limited or weight considerations are critical, such as in the aerospace industry.

Innovations in Material Compatibility: Research and development efforts focused on expanding the range of materials compatible with pneumatic knife holders can open up opportunities in industries dealing with advanced materials. Compatibility with materials like composites or high-strength alloys can address evolving manufacturing needs.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Innovations in Piping: Advancements in Process Technology

Piping systems are the lifelines of many industries, facilitating the transport of fluids, gases, and materials essential for production processes. Over the years, advancements in process technology have revolutionized the design, fabrication, installation, and maintenance of piping systems, leading to increased efficiency, reliability, and safety. In this post, we'll explore some of the latest innovations in piping and their impact on industrial operations.

1. Advanced Materials

One of the significant innovations in piping technology is the development of advanced materials with superior properties, such as corrosion resistance, high temperature tolerance, and enhanced durability. Materials like high-density polyethylene (HDPE), fiberglass-reinforced plastic (FRP), and corrosion-resistant alloys (CRAs) offer alternatives to traditional materials like steel and copper, providing solutions for challenging environments and corrosive fluids.

2. Composite Piping Systems

Composite piping systems, combining materials like thermoplastics, fiberglass, and carbon fiber, offer lightweight, corrosion-resistant, and cost-effective alternatives to traditional metallic piping. These systems are highly versatile and suitable for a wide range of applications, including chemical processing, water treatment, and offshore oil and gas production.

3. 3D Printing Technology

Advancements in 3D printing technology have revolutionized the fabrication of piping components, allowing for rapid prototyping, customization, and on-demand production. Additive manufacturing techniques enable the creation of complex geometries, intricate designs, and customized fittings with reduced lead times and material waste.

4. Smart Piping Systems

The integration of sensors, actuators, and control systems into piping networks has led to the development of smart piping systems capable of real-time monitoring, diagnostics, and predictive maintenance. These systems provide valuable insights into the health and performance of the piping infrastructure, enabling proactive decision-making and minimizing downtime.

5. Modular Piping Solutions

Modular piping solutions, consisting of pre-fabricated components and standardized fittings, offer advantages in terms of ease of installation, flexibility, and scalability. These systems allow for rapid deployment, reduced labor costs, and simplified maintenance, making them ideal for temporary installations, retrofit projects, and fast-track construction schedules.

6. Enhanced Welding Techniques

Innovations in welding technology, such as laser welding, friction stir welding, and robotic welding systems, have improved the efficiency, accuracy, and quality of pipe welding operations. These advanced techniques offer benefits such as reduced distortion, improved joint strength, and increased productivity, particularly in high-volume manufacturing environments.

7. Corrosion Monitoring and Protection

Advanced corrosion monitoring techniques, including ultrasonic testing, electromagnetic inspection, and corrosion-resistant coatings, help identify and mitigate corrosion issues in piping systems. Real-time monitoring systems provide early warning alerts, allowing operators to take corrective action before corrosion leads to leaks or failures.

8. Pipe Rehabilitation Technologies

Innovative pipe rehabilitation technologies, such as pipe lining, pipe bursting, and trenchless pipe replacement, offer cost-effective alternatives to traditional excavation and replacement methods. These techniques minimize disruption to operations, reduce environmental impact, and extend the lifespan of aging piping infrastructure.

9. Digital Twin Technology

Digital twin technology, which creates virtual replicas of physical assets, allows operators to simulate, analyze, and optimize the performance of piping systems in a virtual environment. By integrating real-time data from sensors and IoT devices, digital twins enable predictive maintenance, scenario planning, and performance optimization for enhanced efficiency and reliability.

10. Environmental Sustainability

Innovations in piping technology also focus on environmental sustainability, with initiatives such as water conservation, energy efficiency, and waste reduction. Green piping materials, eco-friendly coatings, and recycling programs contribute to reducing the environmental footprint of piping systems and promoting sustainable practices in industrial operations.

Conclusion

Innovations in piping technology continue to drive advancements in process efficiency, reliability, and safety across various industries. From advanced materials and composite piping systems to 3D printing, smart piping networks, and digital twin technology, the future of piping holds immense potential for trans-formative change. By embracing these innovations and leveraging the latest technologies, companies can enhance their competitiveness, optimize their operations, and meet the evolving challenges of the modern industrial landscape.

#industry#manufacturing#technology#piping system#materials#piping technology#piping solutions#piping network#innovations#piping process

0 notes

Text

Imperial Data Pad

Well, it's winter and it's cold. As is often the case with me, I am fighting the winter blues because the cold and the damp make my bones ache and my connective tissues stiffen like old ironing boards. To counter this, I use the tried and tested method of swearing, sulking and acts of self destruction, such as learning new sports or going too hard with physio therapy to overcome a frozen shoulder, which leads to extra aches and pains.

This year, I have decided to give the complete self destruction a race pass until spring and instead focus my attention onto arts and crafts. To which I have dabbled quite a lot recently, having made the discovery that I am in fact an artist as well as a science graduate. You may be asking why I have talked about my disabilities and then my art? This is because on this occasion, I have combined them in more than one way and I shall explain further, so read on if you would like to know more.

Basically, I really love reading. I read every day and will devour a book in anything from hours, to days or to weeks, depending on the chosen book. However, heavy, thick paper books with fine print are no longer something I can spend my time with due to failing eye sight and painfully arthritic hands. So a few years ago I acquired a Kindle e-Reader and to be honest, it is the best piece of tech I have ever owned and my dear device must be close to ten years old now. I have read hundreds of e-books, some were great classics while some were pure trash. Some of the classics took some work to understand, in particular the philosophical and political works of Hyndeman or Kropotkin and then there was several weeks of my trying to read Marx for fun.

An adaption that the Kindle has, which makes reading so much easier as I approach middle age is that the font size can be made as small or as large as your can comfortably read. Recently, I had noticed that for night time reading, the font size was trending towards the sixteen or eighteen point size. I could wear my reading glasses, but even with font size changed, my biggest problem was light. The Kindle cover I use with my device is now so old and tatty that the flex points are as floppy as old curtains and the LED reading light has significantly dimmed over the years, even with new batteries fitted.

So what was a girl to do? I could go out and buy a new one, the Kindle itself is starting to show the signs of ageing too, being no longer able to fully charge any more and then losing charge in a matter of days rather than previous time gap of weeks. Or maybe I just read too much? However, both Kindle and cover were bought for me by my wife and as such, they have a great deal of sentimental value to me. Luckily, the wife knows that I border on being a crazy artist and despite her saying that I should treat myself to a new device with cover, I think that I can keep these two going for another few years yet. So into the workshop we must go, my dear beloved Kindle.

Step one was the planning and with a simple book cover design, with a built in flip over reading light, the original cover was a rather plain looking design in red PVC fake leather. The edges were fading to white and the spine was threadbare, so it needed some repairs as well as customising with some paint and other fun details. The original light was a single white LED, which I considered changing to a different colour, but I was not sure how that would effect my ability to read in the dark. My next option was to swap out the LED for a brighter white one and then when I took the light unit apart I found that the LED had been wired with a dirty great resistor, which lowered the light output significantly. So I set about fiddling with it to see what I could retrofit and that was when I discovered that the plastic construction of the light unit was somewhat thin and flimsy when it split, before falling apart in my hands. Not to worry, I simply made other plans, involving using a modern pair of LED's mounted on a custom board. Finding the board I wanted to use was easy, I just took a standard LED light and took a hacksaw to it, reattaching as many LEDs as I desired once I was finished cutting, which in this case was just two. I then cut and shaped a new light housing, reflector and set the angle of the LEDs to shine on the middle of the Kindle 'page'.

The rest of the cover needed some inspiration, so with my almost (yeah, right!) fanatical obsession with Star Wars, I set about making the device look like an Imperial Officer's data pad. As always, my choice of media was old bits of cardboard and plenty of cheap super glue. However, for this project I also used riveted snap studs, old knicker elastic and nylon webbing from an old back pack. The front cover still looked fairly plain, so I raided the bottom of the box of making junk and found a moulded plastic sheet that I have used in the past to make realistic looking street cobbles. I don't know what possible function it could have on the cover, but it really does look like is belongs there.

Once I had finished the construction and made it look bright and resplendent, after I sprayed it with my new air brush, with a flat metallic silver paint giving the cover it's smooth shiny gloss, It was time for some fun. This is the bit I enjoy the most, the fun with the filthiest of filth. Using a mix of brown, black, metallic copper and metallic brass paints and then attacking it with sandpaper, I got it looking like it had been through a firefight on the bridge of a Star Destroyer, maybe the Death Star itself. Once it was finished, I hit it with clear coat and left it to harden, while I fiddled with the other parts, such as the new clasp that holds it closed and finally attaching the new light. With it all done I was rather pleased with the outcome. Happily, it is far from perfect because it looks dreadfully dirty, maybe even a little scorched or corroded in places and the previously actual worn out parts have been reinforced nicely. Hopefully, I will get another ten years out of this little beauty.

#amazon kindle#womanartist#star wars art#galactic empire#star wars#disability#fan art#art#lady artist#new artist#custom kindle#air brush art#painting#acrylic paint#amazon books#weathering#imperial officer#book cover#datapad#kindle e-reader#kindletablet

5 notes

·

View notes

Text

Bernie 2020 - Affordable Housing

Invest $1.48 trillion over 10 years in the National Affordable Housing Trust Fund to build, rehabilitate, and preserve the 7.4 million quality, affordable and accessible housing units necessary to eliminate the affordable housing gap

Invest an additional $400 billion to build 2 million mixed-income social housing units, which will help desegregate and integrate communities

Expand USDA’s Section 515 program by $500 million to build new affordable developments in rural areas and protect existing units from being converted to market rate housing

Increase funding for the Indian Housing Block Grant Program to $3 billion to build, preserve, and rehabilitate affordable housing in Indian country

Invest $70 billion to repair and modernize public housing including making all public housing accessible and provide access to high-speed broadband for all public housing residents

Repeal the Faircloth Amendment to allow the construction of new public housing units

Ensure that public housing has high-quality, shared community spaces

Through the Green New Deal, electrify and decarbonize all public housing by conducting deep energy retrofits including appliances, power, and heating

Fully fund tenant-based Section 8 rental assistance at $410 billion over the next 10 years and make it a mandatory funding program for all eligible households

Strengthen the Fair Housing Act and implement a Section 8 non-discrimination law, so landlords can no longer discriminate against low-income families based on their source of income

Expand and strengthen enforcement of the Small Area Fair Market Rent rule to make sure that landlords are fairly compensated when they participate in Section 8, but do not make a windfall from the program

Enact a national cap on annual rent increases at no more than 3% or 1.5 times the Consumer Price Index (whichever is higher) to help prevent the exploitation of tenants at the hands of private landlords

Allow states and cities to pass even stronger rent control standards

Implement a “just-cause” requirement for evictions, which would allow a landlord to evict a tenant only for specific violations and prevent landlords from evicting tenants for arbitrary or retaliatory reasons

Provide $2 billion in federal matching grants for states and localities to provide a right to counsel for persons in eviction or foreclosure proceedings, or at risk of losing their Section 8 rental assistance

Create an office within the Department of Housing and Urban Development to coordinate and work with states and municipalities to strengthen rent control and tenant protections, implement fair and inclusive zoning ordinances, streamline review processes and direct funding where these changes are made

Preempt laws that prevent inclusionary zoning for luxury developments

End exclusionary and restrictive zoning ordinances and replace them with zoning that encourages racial, economic, and disability integration that makes housing more affordable

Encourage zoning and development designed to expand and maximize the number of units fully accessible to people with disabilities

Place a 25% House Flipping tax on speculators who sell a non-owner-occupied property, if sold for more than it was purchased within 5 years of purchase

Impose a 2% Empty Homes tax on the property value of vacant, owned homes to bring more units into the market and curb the use of housing as speculative investment

Encourage “circuit breakers” on property taxes to protect homeowners in gentrifying neighborhoods from being priced out of their own homes as their property values rise

Prioritize 25,000 National Affordable Housing Trust Fund units in the first year to house the homeless

Double McKinney-Vento homelessness assistance grants to more than $26 billion over the next 5 years to build permanent supportive housing

Provide $500 million in funding to states and localities to provide outreach to the homeless to help connect them to case management and social services

Create an independent National Fair Housing Agency similar to the Consumer Financial Protection Bureau dedicated to protecting renters from housing discrimination, investigating landlords who misuse Section 8 vouchers, and enforce housing standards for renters

Create an office within the Fair Housing Agency to protect mobile home residents from housing discrimination, rent instability, and unjust evictions

Fully fund the Fair Housing Assistance and Fair Housing Initiatives Programs at $1 billion over the next 10 years

Pass the Equality Act to include LGBTQ+ Americans in the Fair Housing Act

Implement the Affirmatively Furthering Fair Housing rule blocked by President Trump’s administration to ensure that federal funds will promote fair housing

Enforce the Olmstead decision, Section 504, and the Americans with Disabilities Act to ensure access to accessible, integrated housing

Make sure that people who have served their time are not excluded from public housing

Ensure that no survivor of domestic violence can be evicted on the basis of their assault

Guarantee that renters have the right to form tenants unions free from retaliation by landlords or managing agents

Invest $50 billion over 10 years to provide grants to start and expand community land trusts and other shared equity homeownership models

Invest an additional $15 billion to enact a 21st Century Homestead Act, based on the work of Mehrsa Baradaran, to purchase and revitalize abandoned properties to create community and individual wealth and assets for historically disadvantaged communities

Instruct HUD to assist communities establishing shared equity homeownership by ensuring they can access existing federal housing programs, and help new organizations build the necessary capacity to succeed

Invest an additional $2 billion at USDA and an additional $6 billion at HUD to create a first-time homebuyer assistance program that will increase home ownership

Expand pre-purchase housing counseling to all prospective homebuyers

End the mass sale of mortgages to Wall Street vulture funds and thoroughly investigate and regulate the practices of large rental housing investors and owners

Make data such as evictions, rent increases, and safety violations for large landlords available to the public and the Department of Housing and Urban Development

Increase enforcement to protect families against fraudulent, deceptive, and abusive lending practices and ensure all mortgage costs are clear, risks are visible, and nothing is buried in fine print

Implement legislation to prevent abusive “contract for deed” transactions and use existing authority to protect communities of color, which for too long have been exploited by this practice

Create a commission to establish a financial relief program to the victims of predatory lending, mortgage fraud, redlining and those who are still underwater on their mortgages as a result of the 2008 Wall Street crash

Perform energy efficiency upgrades to make buildings more energy efficient and lower energy bills

Provide grants for low- and moderate-income families and small businesses to invest in weatherizing and retrofitting their homes and businesses

Replace all mobile homes with quality zero-energy modular homes

Provide grants for low- and moderate-income families to invest in cheaper electricity for these needs

Expand the Low-Income Home Energy Assistance Program (LIHEAP) to help low-income families pay their heating and cooling bills

Issues List

#Affordable Housing#Housing#Homelessness#End homelessness#equality act#green new deal#Bernie Sanders#Bernie 2020#Our Revolution#Feel the Bern#NotMeUs#Not me us#US Politics#politicians

125 notes

·

View notes

Text

The 10 Green Building Principles aiming to get real estate to net-zero

An eco-friendly 3D-printed house made entirely of sustainable recyclable materials in Ravenna, Italy

Net zero commitments have surged this year as cities, investors, businesses and educational institutions signal their intent to help create a more sustainable future. This shared ambition, boosted by the UN’s Race to Zero[1] campaign, indicates that we are moving in the right direction. But we need more. Next year must be when we turn talk into tangible action plans.

Real estate and the built environment – responsible for close to 40% of global carbon emissions – have a significant role to play. JLL’s Decarbonising the Built Environment[2] report found that only 18% of organizations have an action plan for their real estate portfolio. While much attention is focused on new, state-of-the-art buildings that achieve the highest sustainability certifications, 70% of buildings that exist today will still be here in 2050, highlighting the need to repurpose spaces, retrofit older buildings and refurbish in line with circular economy principles.

Companies needed a roadmap to get their real estate to net zero carbon emissions. Now they have one. To guide real estate investors and occupiers on implementing and achieving their net zero carbon targets across their portfolios, JLL has partnered with the World Economic Forum to establish 10 Green Building Principles[3]. It also complements existing initiatives, for example by explaining what companies need to do to deliver against the WorldGBC Net Zero Carbon Buildings Commitment.

The 10 Green Building Principles cover five key areas:

1. Adopting a data-driven approach

One of the first steps is knowing exactly what needs to be addressed. Businesses need to calculate a robust carbon footprint of their portfolios in the most recent representative year to inform targets.

2. Setting goals along the journey

The scale of the challenge facing us in the coming decades is daunting. It’s important that companies set a target year for achieving net-zero carbon as part of their longer-term strategy. This needs to be no later than 2050, though we’re seeing many companies and governments aim for sooner. Our new principles recommend interim targets for reducing at least 50% of these emissions by 2030.

3. Tackling embodied carbon

Businesses need to maximize emissions reductions for all new developments and major refurbishments in the pipeline to ensure delivery of net-zero carbon by their final target year.

Measuring and recording the embodied carbon emissions associated with the materials and construction processes for new developments and major refurbishments is essential. The World Green Building Council estimates it will account for half of the entire carbon footprint of new construction between now and 2050. Reducing it through measures such as low-carbon materials, modular construction and implementing a circular economy approach will be a critical factor in real estate’s ability to reach net zero.

4. Focusing on clean energy

Reducing the energy buildings consume is central to a net zero future. This means businesses need to drive energy optimization across both existing assets and new developments. They also need to maximize the supply of on-site renewable energy, and make sure all off-site energy is procured from renewable-backed sources where available.

Any residual emissions need to be compensated for by purchasing high-quality carbon offsets. A lot of guidance has come out in the past year, but there’s more to come, especially through the SBTi’s Net-Zero Standard.

5. Collaborating widely

Reaching net-zero carbon emissions by 2050 is going to require teamwork at nearly every stage. Our principles call for engaging with stakeholders in the value chain to reduce Scope 3 emissions (indirect emissions in the wider value chain). Businesses also need to develop more partnerships to better identify opportunities and equitably share the costs and benefits of interventions.

There is no time to waste. Investors and occupiers need to deliver against the commitments they have boldly laid out in the last year. With the 10 Green Principles framework, it’s no longer a question of how can we reach net zero, but how can we push ourselves to get there faster. Let’s build on the momentum and make 2022 the year that real estate turns commitments into action.

Source

Christian Ulbrich, The 10 Green Building Principles aiming to get real estate to net-zero, in: World Economic Forum, 3-11-2021, https://www.weforum.org/agenda/2021/11/10-green-building-principles-real-estate-net-zero/?utm_source=facebook&utm_medium=social_video&utm_term=1_1&utm_content=24685_Bangladeshi_architect_monsoon_proof&utm_campaign=social_video_2022

[1] https://unfccc.int/climate-action/race-to-zero-campaign [2] https://www.jll.co.uk/en/trends-and-insights/research/decarbonizing-the-built-environment [3] https://www3.weforum.org/docs/WEF_Green_Building_Principles_2021.pdf

1 note

·

View note

Text

3D Printing Dubai automobile parts

3D Printing Dubai automobile parts - Customizations, Retrofits, unique interiors, and low volumeparts for luxury vehicles is possible with 3D Printing. 3D printed automobile parts are an ideal solution for customization of vehicles for specialized use, personal preferences and for luxury vehicles that are only produced in a limited production run, so large numbers of mass produced parts are not required.

Using 3D printers to create automotive parts, interiors and accessories is a cost-effective means of production avoiding the expense and time needed for tooling. Parts can easily be printed without requiring a factory production line, meaning limitless customization is possible. Vehicles that need to be adapted for special needs and emergency response can be retrofitted with new 3D printed panels, parts and equipment quickly and on-demand based on requirements.

With a number of strong and lightweight materials to choose from, 3D printed automotive parts are a realistic option to traditional manufacturing and are being used extensively in the automotive sector. Parts can be designed and manufactured in more efficient and innovative ways, avoiding many unnecessary assembly processes that 3D printed parts no longer require due to the possibility of being able to print part geometry in one piece. Luxury vehicle manufacturers are slowly replacing some metal parts with 3D printed high performance thermoplastic parts, to reduce time to market and create parts that can provide electrical insulation and other properties not available from metal.

Suppliers of automotive parts: Perform design verification, and form fit and function testing of automotive parts with 3D functional prototypes.

Replicas and scale models: Using 3D CAD data 3D scale models can be directly and accurately produced for new concept cars without the need for handworked models.

Inoventive 3D Printing Dubai, the largest 3D Printing company can undertake any types of 3D Printing projects and can do its fastest delivery. Call/ WhatsApp: +971 52 595 9616 | Email: [email protected] | https://3dprintingdubai.ae/

https://3dprintingdubai.ae/3d-printing-dubai-automobile-parts/

0 notes

Link

0 notes

Text

Colordyne Technologies adopts new Fiery Impress print server

Converters have new, high-quality, cost-effective options for hybrid flexo/digital production of premium labels, thanks to a new solution at Labelexpo Americas that delivers more power than ever before.

Colordyne Technologies, a leading manufacturer of efficient, high-resolution digital inkjet printers and retrofits, is partnering with Fiery, Electronics For Imaging’s industry-leading developer of advanced servers for digital color print production, to be the first manufacturer in the world delivering UV-LED and water-based inkjet solutions that feature the market-proven, high-end prep and processing workflow capabilities of the Fiery Impress digital front end (DFE).

Colordyne’s high-speed, high-resolution process color inkjet print engines, on display at Stand 5923 in the tradeshow Labelexpo Americas 2022 taking place from 13-15 September, feature the Fiery Impress DFE, a brand new, turnkey inkjet print server technology.

Colordyne’s inkjet engines driven by Fiery print server technology offer premium quality inkjet production for durable UV-LED labels and water-based ink printing ideal for food and beverage and other CPG brands seeking eco-friendly, sustainable labels.

Customers can easily integrate Colordyne’s inkjet engines on existing flexo and convert equipment to create an affordable single-pass hybrid printing press or employ it as a standalone digital production press. The print engines support up to seven colors with options for CMYK, white and additional process colors.

Affordable management

“Using Fiery Impress with our 3800 Series inkjet engines, converters can retrofit their existing flexo presses at approximately half the cost of a new hybrid narrow web press,” said Taylor Buckthorpe, director of sales and marketing, Colordyne Technologies. “The comprehensive set of integrated Fiery products add a wealth of capabilities throughout the print process, helping manufacturing facilities produce more with their presses. When it comes to next-level automation and color management, we look at Fiery as the strongest partner to work with. Together, we will help converters drive efficiencies while increasing quality and reliability as they grow their businesses with digital print.”

With over two million servers installed worldwide, Fiery technology is the leading DFE in digital printing. The launch of the Impress DFE – a ready-to-go, an off-the-shelf platform that requires less time and less cost for hardware integration – streamlines the process needed to bring Fiery technology to new industrial and packaging applications.

The new Fiery offering helps ensure users can complete more jobs per shift thanks to a suite of file preparation and make-ready tools to automate many prepress tasks. Fiery Impress technology efficiently handles color management, including extended color gamuts beyond CMYK, while delivering accurate ink cost estimates to help converters ensure profitability. Additional tools, such as Fiery JobFlow prepress automation workflow software, can eliminate manual step-and-repeat work to help converters get digital and hybrid jobs to press faster.

Digital and cloud capabilities

Converters can also take advantage of more opportunities in multi-SKU, versioning, and serialization by using a Fiery Impress DFE streaming option which delivers powerful RIP-while-printing capabilities for continuous, high-volume, variable-data printing.

The Fiery Impress DFE delivers consistent, predictable results that match a designer’s intent with industry-standard native Adobe PDF print engine processing and PDF 2.0 support – a key competitive advantage not available in other RIP solutions.

Fiery Command WorkStation – the 1 operator interface for digital print job management – comes standard with the Fiery Impress DFE. Plus, Colordyne 3800 Series users can use the server to connect with a full suite of free and paid EFI IQ cloud business intelligence and analytics solutions. The Fiery Impress DFE can also integrate with leading label and packaging MIS platforms, connecting converters’ digital operations to company-wide workflows.

“Fiery DFEs have long been known for delivering superior color, image quality, and efficiency, and our Fiery Impress DFE brings those capabilities to new markets, including labels, packaging, and inline manufacturing,” said John Henze, vice president of sales and marketing, EFI Fiery. “This exciting new partnership with Colordyne Technologies represents an important market opportunity that combines the industry’s leading DFE technology with Colordyne’s remarkable inkjet engines for hybrid and digital label converting.”

The Fiery Impress DFE is the first technology for Colordyne equipment capable of supporting the Adobe PDF Print Engine (APPE) for a native, end-to-end PDF workflow using the industry’s leading rendering technology. Support for APPE gives users the advantage of optimal output using the industry’s leading rendering technology, optimizing the appearance of transparency blends, overprinting, spot colors, trapping, and more.

“The Fiery Impress DFE will open doors to new opportunities in manufacturing workflows, especially for labeled products,” said Mark Lewiecki, senior product manager, Adobe. “Colordyne customers will benefit from the power of the Adobe PDF Print Engine, built on the same Adobe technologies employed by Adobe Acrobat and Illustrator CC. The result is maximum reliability, from design to proof to final output. Adobe and EFI continue to bring innovative technologies to market. We are happy to see that Colordyne and its customers will show the way forward in this dynamic growth segment.”

With its new, advanced workflow, Colordyne’s retrofit technology at Labelexpo Americas is a reliable and effective upgrade in the power and flexibility converters need to meet new market opportunities.

“Inkjet is important for growth-minded flexo converters, but the bigger opportunity comes with color capabilities and workflow advantages over a basic inkjet integration,” according to industry analyst Marco Boer of IT Strategies. “In a crowded field where there are many niche digital inkjet integrators, choosing one that offers a robust DFE workflow and extended gamut inks at a competitive investment cost can create a differentiating advantage in label production.”

0 notes

Text

HVAC Market, by HVAC Type, Demand 2021

According to BlueWeave Consulting, The global HVAC Market stood at USD 145 billion in 2018 and is projected to reach USD 183 billion by 2025 with a CAGR of 3.2%. Rising infrastructure and construction activities, along with the focus on the adoption of energy-efficient HVAC systems, is anticipated to fuel the demand for HVAC across the globe in the coming years. Moisture regulation is essential for both building and personal health. A high level of moisture can cause mold and decay growth, and a lesser amount makes discomfort and temperature loss. HVAC system offers moisture regulation as a part of the system’s process, make sure that an optimum moisture level is regulated and dependable.

Technological trends that are driving the market growth such as movement-activated Air Conditioning, Thermally Driven Air Conditioning, On-Demand Hot Water Re-circulator, Ice-Powered Air Conditioning. Other trends like Dual-Fuel Heat Pumps, Sensor-Enhanced Ventilation, Geothermal Heat Pumps, Smart Homes, 3-D Printed Air Conditioners, and Harnessing Heat from a Computer are also pushing up the market.

Rising R&D expenditures and activities by the leading players are impacting the growth of the market positively. Additionally, more proficient heating and air conditioning units offer more options for air circulation and moving air throughout the surroundings than ever before. The usage of fans and air strainers will expand the air quality of atmospheres while also producing a more common temperature. Since the technology used to build HVAC systems has enhanced together with better manufacturing resources, these systems are now durable and energy-efficient.

Browse Detailed Analysis with TOC, “Global HVAC Market, by HVAC Type (Heating [Furnaces, Heat Pumps, Boilers], Ventilation [Humidifiers/Dehumidifiers, Air Cleaners, Ventilation Fans], Cooling [Ducted Split/Packaged Unit, Split Units, Chillers]), by End-User (Commercial, Industrial and Residential), By Regions (North America, Europe, Asia Pacific, Middle East & Africa and Latin America); Trend Analysis, Competitive Market Share & Forecast, 2015-2025”

At https://www.blueweaveconsulting.com/report/global-hvac-market-bwc19280/report-sample

Among Type, the Cooling segment is the fastest growing market and expected to showcase a substantial growth rate over the forecast period.

Increasing temperature and changing climate across the globe are accelerating the demand for cooling systems. High efficient systems help to reduce the power bills and provide a high level of comfort. The increasing number of connected home devices equipped with wireless technology is expected to boost the demand for cooling systems across the globe.

Among End-User, Commercial category is leading the market and anticipated to grow at significant CAGR over the forecast period.

The commercial is the leading end-user segment, mainly driven by the increasing number of workstations and buildings and emerging hospitality sector worldwide. Enduring industrialization and growing income levels in evolving nations and the large connected base of HVAC systems in developed countries, which creates stable replacement demand favoring the growth of the market.

Asia-Pacific is the dominating region and estimated to project momentous growth in the coming years.

Increasing customer demand for comfort cooling and government incentives encouraging energy-efficient HVAC systems to decrease greenhouse gas emissions are accelerating the growth of the HVAC market in the region. High installation and maintenance expenditure coupled with complications of retrofit HVAC connections may hamper the market growth. Though, many leading manufacturers are capitalizing in R&D to progress cost- and energy-efficient units, which will boost the product demand.

Competitive Landscape

The major players in the global HVAC market include Johnson Controls International PLC, Daikin Industries Ltd, Gree Electric Appliances, Samsung Electronics Co. Ltd, Lennox International Inc., LG Electronics Inc, , Danfoss, Carrier Corporation, Mitsubishi Electric Corporation, Haier, Other Prominent players.

About Us

BlueWeave Consulting provides comprehensive Market Intelligence (MI) Solutions to businesses regarding various products and services online and offline. We offer all-inclusive market research reports by analyzing both qualitative and quantitative data to boost up the performance of your business solutions. BWC has built its reputation from the scratch by delivering quality inputs and nourishing long-lasting relationships with its clients. We are one of the promising digital MI solutions companies providing agile assistance to make your business endeavors successful.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

The Uses & Benefits Of Paper Mill Automation

Having your very own intensive comprehension machine execution can just get you up until this point. In case you're meaning to improve your energy efficiency or generally paper machine productivity, it may profit you to comprehend the current business or evaluation explicit midpoints to recognize zones for development and their need for consideration. By acquiring a free viewpoint, you can set up reasonable targets dependent on data for your industry. Automation solutions have made the work easy.

The electronic age has arrived. That is uplifting news for most of ventures searching for quicker, more proficient approaches to share data. Its terrible news, it appears, for the paper business. Consider everything: When was the last time you got a soft cover book versus downloading the novel onto a tablet? Do you stop to get the day by day paper or perused the headlines on your Smartphone? Also, when there is a significant organization meeting, do colleagues demand a printed version of the PowerPoint or do they ask that you email it to them?

The paper industry has been exposed to problematic advanced innovation that has undermined the actual work of some companies. To those ends that have put the "luddite" mark on the pulp and paper industry in view of its lethargic reflexes with regards to receiving new technology. With a ton of capital investment in apparatus that, sometimes, is many years old, in addition to the old thought that there will consistently be a need for pen and paper, maybe it is nothing unexpected that paper manufacturers were hit hard by the digital revolution. The Paper mill automation plays an important role.

Automation of data collection improves exactness and diminishes costs. Such expanded precision empowers organization supervisors to settle on better choices. These frameworks make Paper mill automation feasible for production lines and mechanical cycles, permitting a consistent mass production day in and day out. 24 hours per day, seven days every week, this improves profitability and lessens get together occasions. By and by, a portion of these paper companies have endure an industry obstruction, however they are flourishing—and are currently showing different enterprises some things about enduring a problematic innovation storm.

The new mantra in this energy-and crude materials-serious industry: Make more items with less energy. There is the same old thing in the general cycle. There is anything but another approach to make paper—it is a time tested interaction. The genuine chance is around effectiveness—putting resources into new cycles, new innovation and new abilities that will diminish utilization and make more items with less energy. With the assistance of automation solutions and programming sellers, organizations like International Paper mill automation industries are demonstrating their innovation ability.

The pulp and Paper mill automation industry gets unfavorable criticism. We must be creative. So inventive, truth be told, that International Paper has sorted out some way to adjust, change and reevaluate itself to oblige the market. In particular, traditional paper mills are situated for development in new product territories, for example, industrial packaging, food compartments, creased boxes, tissue and cushion mash—utilized in diapers—which is huge in the growing Asia-Pacific market. It's simply an issue of reconsidering, repositioning, retraining and some gear retrofitting. Also, find out about Corrugating automation.

0 notes

Text

North America LPG Vehicles Market Global Industry Analysis Size, Share, Trends and Profitable Segments Breakdown and Detailed Analysis of Current and Future Industry Figures till 2027|Key Players Fiat Chrysler Automobiles, Daimler Trucks North America LLC, Turtle Top, Inc., Blue Bird Corporation

North America LPG vehicles market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, company strengths and weaknesses, product launch, clinical trials pipelines, product approvals, patents, product width and breadth, application dominance, technology lifeline curve. The below data points provided are only related to the companies’ focus related to LPG Vehicles market. This LPG vehicles market report provides details of market share, new developments, and product pipeline analysis, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, product approvals, strategic decisions, product launches, geographic expansions, and technological innovations in the market. To understand the analysis and the market scenario contact us for an Analyst Brief, our team will help you create a revenue impact solution to achieve your desired goal.

LPG vehicle is also known as propane or autogas vehicle. The LPG family contains various hydrocarbon gases which are liquefied with the help of pressurization process and then it is used as fuel in vehicles. The major benefit of using propane is that it shows best performance in cold weather. Moreover, these LPG vehicles are highly economical, clean, reliable, eco-friendly and safe. The growing government norms for cutting down the carbon foot print from the environment has enforced the automaker to manufacture such type of vehicles that are eco-friendly. This would probably accelerate the demand for the propane vehicles in the coming years.

North America LPG Vehicles Market By Vehicle Intake System Type (LPG Liquid Phase direct Injection (LPDI), LPG liquid Injection System (LPI), LPG Vapour phase injection (VPI) and LPG Converter-and-mixer systems), Fuel Type (Bio Fuel LPG and Mono LPG), Vehicle Type (Light Commercial Vehicle, Passenger Cars, Heavy Commercial Vehicle), Sales Channel (OEMs and Aftermarket), Country (U.S, Canada and Mexico) Market Trends and Forecast to 2027 LPG vehicles market is expected to gain market growth in the forecast period of 2018 to 2027. Data Bridge Market Research analyses that the market is growing with a CAGR of 6.3% in the forecast period of 2020 to 2027 and expected to reach USD 1,836.72 million by 2027 from USD 1,134.73 million in 2019. Increasing demand for duel fuel vehicles that allows the customer to cut down their running cost of the vehicles is prominent factor that drives the growth of the market.

Get a Sample Request on North America LPG Vehicles Market @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=north-america-lpg-vehicles-market

LPG Vehicles Market Country Level Analysis:

North America LPG vehicles market is analyzed and market size information is provided on the basis of vehicle intake system type, fuel type, vehicle type and sales channel as referenced above.

The countries covered in the LPG vehicles market report are U.S, Canada and Mexico The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as new sales, replacement sales, country demographics, and regulatory act and import-export tariffs are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of sales channels are considered while providing forecast analysis of the country data.

High Investment by Automakers has Fuel the Growth of LPG Vehicles Market:

North America LPG vehicles market also provides you with detailed market analysis for every country growth in installed base of different kind of products for LPG vehicles market, impact of technology using life line curves and changes in automobile regulatory scenarios and their impact on the LPG vehicles Market. The data is available for historic period 2010 to 2018.

LPG Vehicles Market Scope and Market Size:

LPG vehicles market is segmented on the basis of vehicle intake system type, fuel type, and vehicle type and sales channel. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of vehicle intake system type, the market is segmented into LPG converter and mixer systems, LPG vapour phase injection (VPI), LPG liquid injection system (LPI) and LPG liquid phase direct injection (LPDI). Liquid Phase direct Injection (LPDI) holds largest market share in the North America LPG vehicles market, the rising conversion of vehicles has increased the demand for the liquid phase direct injection. This technology is highly eco-friendly and while filling LPG liquid in the vehicles it does not emits harmful gas in the environment.

On the basis of fuel type, the market is segmented into mono LPG and bio-fuel LPG. Bio fuel LPG has accounted largest segment as this fuel emits less carbon in the environment and also it enhances fuel efficiency.

The major players covered in the report are Fiat Chrysler Automobiles, Daimler Trucks North America LLC, Turtle Top, Inc., Blue Bird Corporation, REV Group, StarCraft Bus, Isuzu Commercial Truck of America, Inc. (A subsidiary of ISUZU MOTORS LIMITED) Commercial Truck of America, Inc., Ford Motor Company, General Motors, Toyota Motor Sales, U.S.A., Inc. (A subsidiary of TOYOTA MOTOR CORPORATION) and Honda Motor Co., Ltd. among other players domestic and global. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

North America LPG Vehicles Market, By Fuel Type:

On the basis of vehicle type, the market is segmented into passenger cars, light commercial vehicle, and heavy commercial vehicle. The increasing logistic sector has result in increasing the demand for the light commercial vehicles .These vehicles carry good and public in the bulk that result in saving the running costs.

On the basis of sales channel, the market is segmented into OEMs and aftermarket or retrofit vehicle utilities and others. The rising government initiatives and regulations towards reducing greenhouse emissions has impulse OEMs such as Ford, Toyota, General Motors and others to increase their production towards eco- friendly vehicles. This factor has increased the production of LPG vehicle.

Get Table of Content on Request @ https://www.databridgemarketresearch.com/toc/?dbmr=north-america-lpg-vehicles-market

Reasons for buying this North America LPG Vehicles Market:

Laser Capture North America LPG Vehicles Market aids in understanding the crucial product segments and their perspective.

Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Laser Capture North America LPG Vehicles Market.

Even the Laser Capture North America LPG Vehicles Market economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

This report provides a more rapid standpoint on various driving facets or controlling Medical Robotic System promote advantage.

This worldwide Locomotive report provides a pinpoint test for shifting dynamics that are competitive.

The key questions answered in this report:

What will be the Market Size and Growth Rate in the forecast year?

What is the Key Factors driving Laser North America LPG Vehicles Market?

What are the Risks and Challenges in front of the market?

Who are the Key Vendors in Global North America LPG Vehicles Market?

What are the Trending Factors influencing the market shares?

What is the Key Outcomes of Porter’s five forces model

Access Full Report: https://www.databridgemarketresearch.com/reports/north-america-lpg-vehicles-market

Browse Related Report:

CNG and LPG Vehicles Market

SUV Market

Rack Stacker Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes